The fluidized bed has a circular structure to avoid dead corners.

The hopper is equipped with stirring to avoid the agglomeration of damp materials and the formation of ditch flow during drying.

The use of tipping particles is convenient, rapid, and thorough, and an automatic feeding and discharging system can also be designed according to requirements.

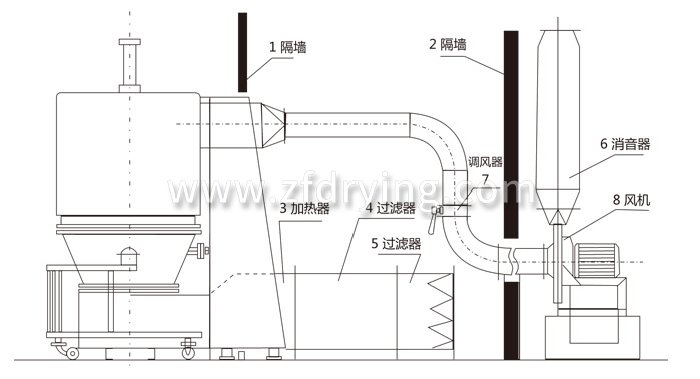

Seal the negative pressure operation, and the airflow is filtered. Easy to operate and clean.

The drying speed is fast, the temperature is uniform, and the drying time for each batch is generally 20-30 minutes, depending on the material.

|

project |

model | ||||||

| Feeding (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan power (kW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Mixing power (kW) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Mixing speed (rpm) | 8~11 | ||||||

| Steam consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operation time (min) | 15-30(Revised according to material characteristics) | ||||||

| Host height | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

Related Information

Troubleshooting and maintenance for centrifugal spray dryers should focus on core systems, encompassing atomization, hot …

Characteristics and Applications of Centrifugal Spray Dryers (Centrifugal Spray Dryers) are as follows:I. Characteristics…

Centrifugal spray dryers demonstrate significant advantages in drying efficiency, product quality, operational convenienc…

Feedback

Take a screenshot and recognize the QR code

Zhifang Drying